iNOEX GmbH and NAFFCO Flow Control: A Partnership Redefining Success

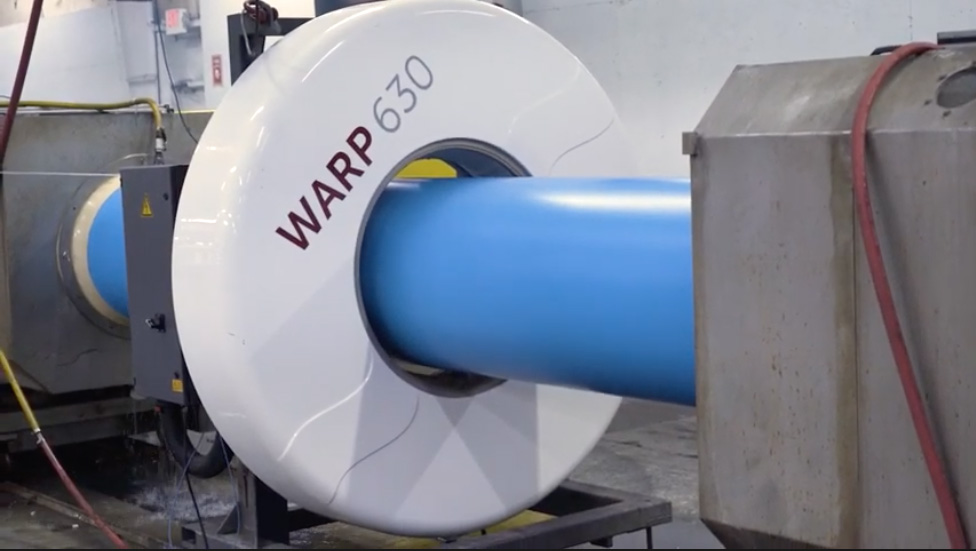

NAFFCO was established in Dubai, UAE in 1991 to be a leading manufacturer of fire fighting equipment, fire protection systems and piping systems. Over the years, NAFFCO has remained committed to investing in production and quality control equipment. iNOEX is very proud to say that today we have a large number of WARP radar units operating not only in the headquarters in Dubai, but also in the Kingdom of Saudi Arabia and in the USA.

Currently, NAFFCO has the highest number of iNOEX installations in the Middle East with the iNOEX gravimetric and radar inline measuring system. It provides detailed process quality data that can help save time in adjusting wall thickness during startup, reduce startup costs and improve startup rate, but also saves NAFFCO from startup waste. Learn how iNOEX' SAVEOMAT gravimetric systems, WARP radar-based measurement systems and the iDM 4.0 Data Manager help reduce material cost and improves quality.