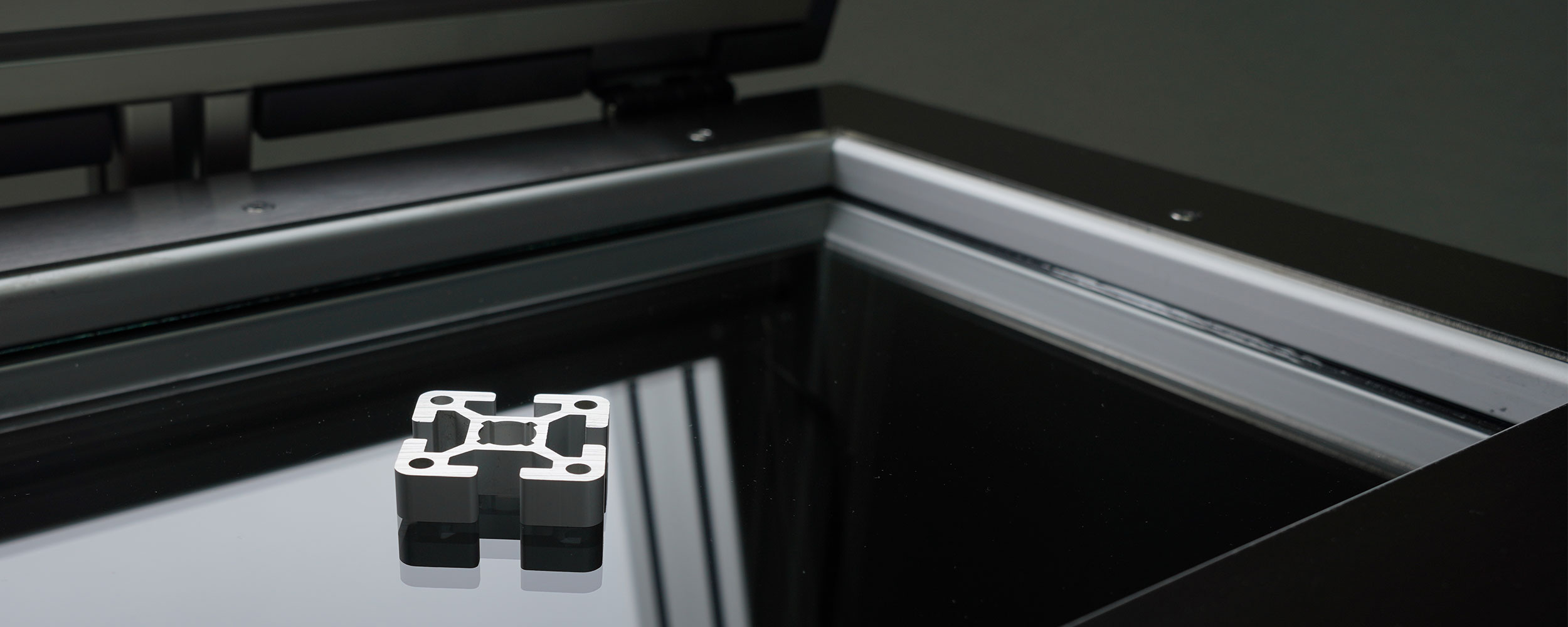

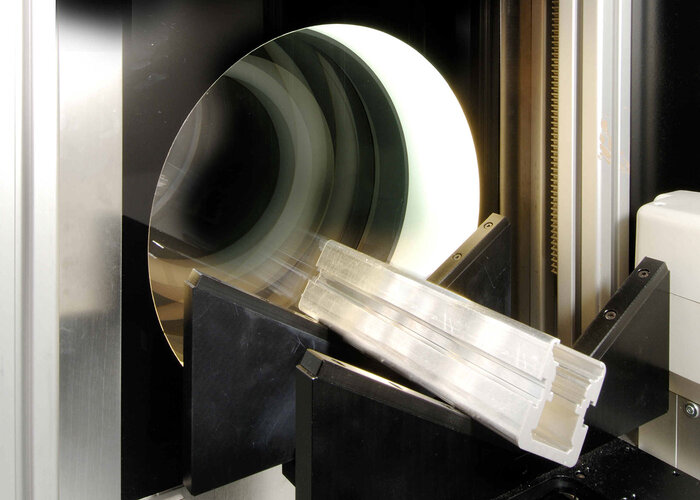

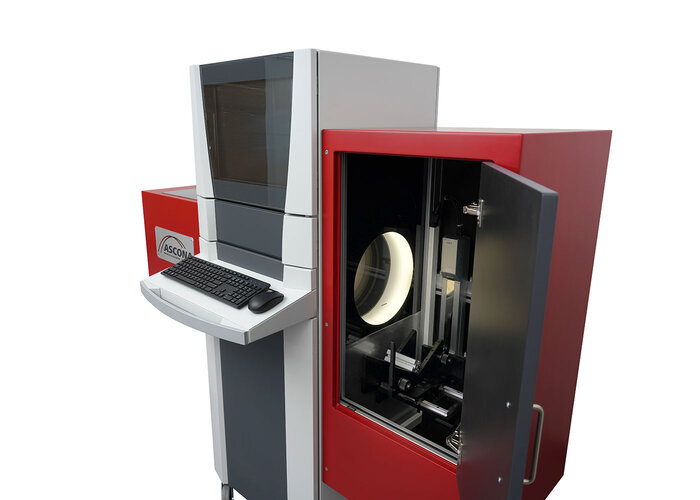

Various types of surface inspection and dimensional measuring systems for aluminium and plastic profiles for fast measuring results with maximum user-friendliness.

Partnership iNOEX and ASCONA

The cooperation of iNOEX and ASCONA provides high quality hardware and software solutions and excellent service in the aluminium, plastic and rubber profile extrusion.

ASCONA GmbH is the specialist for optical measuring systems for dimensional measurement and surface inspection technology based in Oberteuringen, Germany.

iNOEX LLC, USA and iNOEX SIST, China are the exclusive ASCONA partners. This means there are local sales and service partners for the promex product lines in North America (Canada, Mexico and the USA) and China. For all other worldwide markets, please contact the ASCONA team directly. Learn more at www.ascona-gmbh.de