Sustainability, reduced material consumption, increasing quality standards and extensive process automation are the crucial future topics. The overall term Industrial Packaging encompasses various applications (such as drums, liners, IBC containers, tanks and canisters) and manufacturing processes (such as blow molding, rotational molding and extrusion), which also have to meet the challenges mentioned above.

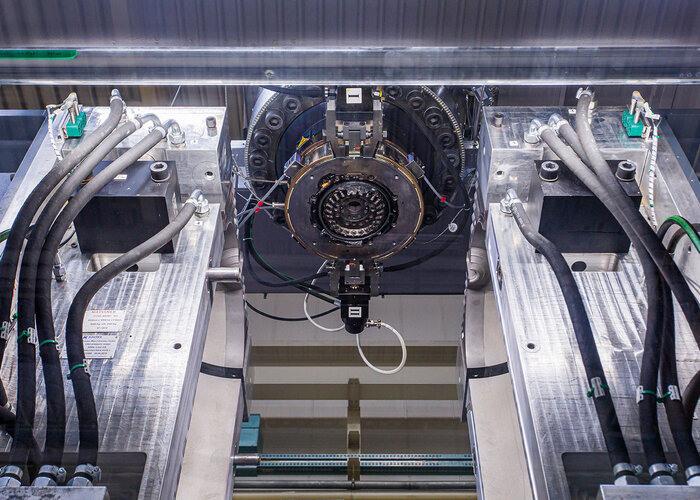

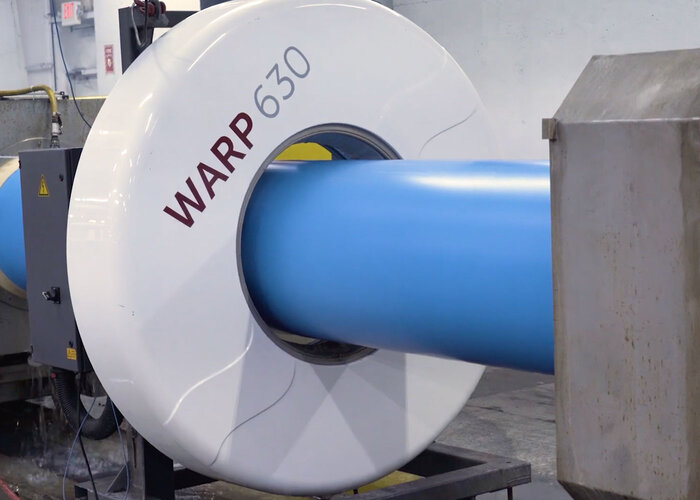

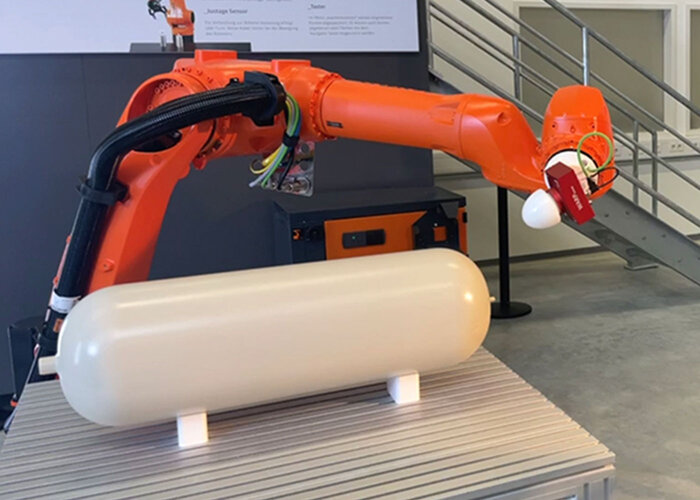

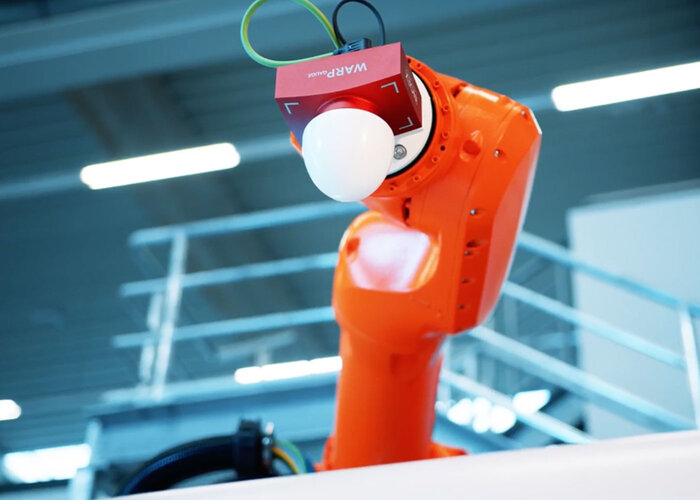

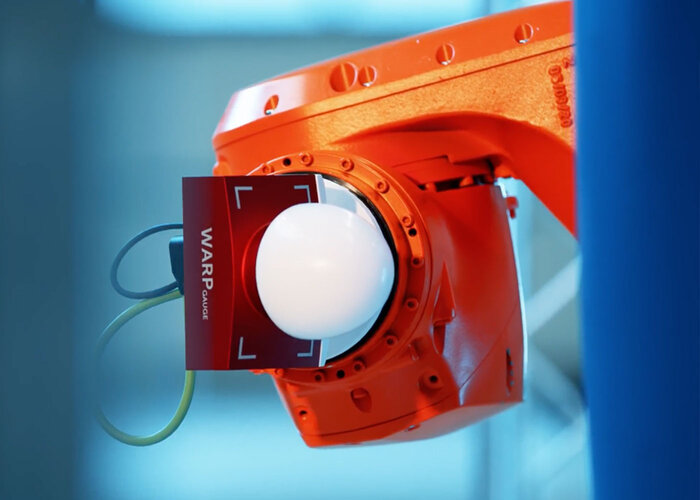

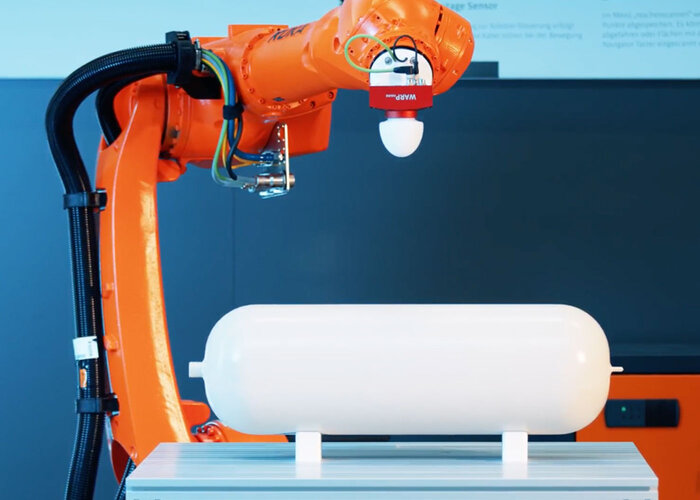

For the first time, iNOEX radar technology offers the possibility of comprehensively, automatically and non-destructively recording quality data of products in these areas and using them for process control purposes. This includes wall thicknesses, component dimensions and component-specific geometrical features. The measuring systems can also be used for documenting component quality or for incoming goods inspection.

Labour-intensive manual component measurements using ultrasonic or magnetic measurement, as well as labour-intensive destructive component analyses, are eliminated or significantly reduced. Automated radar measuring systems pave the way from spot quality control to 100 % control. The so-called free testing of entire production batches can be eliminated if necessary and users can react much earlier to process or material-related changes.

Further information and insights into the basics of radar technology, as well as the functioning of sensors, are explained in the Industrial Packaging section. Furthermore, manufacturing processes, various applications and corresponding automation steps are presented.