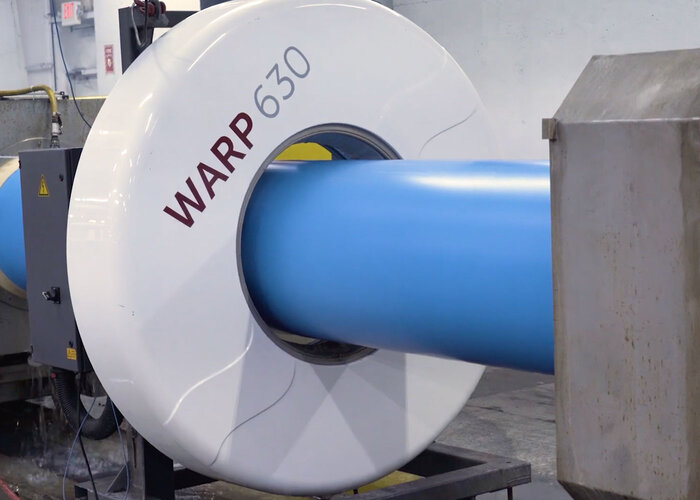

In the extrusion of plastic pipes, a wide range of products (such as gas and pressure pipes, hot water pipes, sewage pipes, etc.) are covered, as well as various materials (such as PP, PE, PVC, PA, PVDF, etc.) are used. Withstanding enormous pressure loads, maintaining the prescribed wall thicknesses and ensuring flawless processing are just some of the crucial requirements. iNOEX uses radar technology, among other things, to meet these challenges. In addition to increasing product quality and providing comprehensive documentation, material savings are a key focus for customers. For this purpose, inline measuring systems are used in the extrusion area, which cover the pipe up to 100 % in the circumferential and longitudinal directions, as well as the WARP portable. The handheld measuring device is used for measurements in the medium and large pipe range to enable further optimization steps through very early measurements. All radar measuring systems play a decisive role in automation and process control.

Years of experience in the field of pipe extrusion have made it possible for iNOEX to use this comprehensive knowledge now also in the field of Industrial Packaging and make it accessible for further manufacturing processes in the field of plastics technology. The underlying goals (such as process transparency, material savings, process control) are comparable. Synergies have arisen between the two areas through continuous further development in radar technology, such as the measurement of ever thinner wall thicknesses.

Radar technology in extrusion:

- Continuous measurement of wall thickness, diameter and eccentricity with up to 100 % pipe coverage

- Intuitive operation and easy adaptation of the measuring system to different product diameters

- Measurement technology proven in an industrial environment

- Process and quality data for process analysis and automation as well as for complete documentation

- Significant material savings enable a quick return on investment

Subscribe to the newsletter

Subscribe to the newsletter and never miss exciting news about product development, events and internal topics from the iNOEX world again.

Thank you for your subscription!

We have sent you an email — please confirm your email address by clicking the activation link in it.