Blow molding is used to manufacture various hollow objects, such as barrels, liners for hydrogen pressure vessels, IBC containers or canisters. All of these applications can be measured using radar technology. A prerequisite for measurement is a wall thickness of more than 2 mm and the ability to position the radar sensor perpendicular to the surface of the component.

Measurement using radar technology can be performed on the finished component or directly on the extruded melted tube. Thanks to the automated measurement data, the component quality can be continuously evaluated, potential changes identified and ultimately the process can be controlled based on real measurement values. The wall thickness information from the sensor is used to adjust the wall thickness profile (WDS) as well as for partial wall thickness control (PWDS®). Even without controlling the process, precise quality data is crucial to monitor quality-critical products and document the quality.

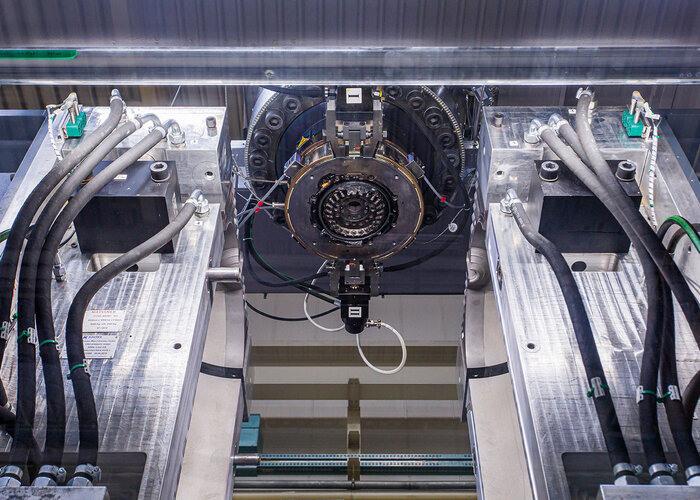

The WARP GAUGE sensor provides a flexible, automated solution for blow molding. With the WARP portable, measurement data can be easily and non-destructively taken manually. Both solutions replace destructive or cumbersome testing methods and save valuable time in quality assurance.

Radar technology for blow molding:

- Simple, automated measurement data acquisition

- Adaptable to product geometry via kinematics

- Key to process control due to excellent measurement data quality and quantity

- Linking sensor and kinematic data also enables contour and distortion

measurement of components - Material savings and more uniform wall thickness distribution

Subscribe to the newsletter

Subscribe to the newsletter and never miss exciting news about product development, events and internal topics from the iNOEX world again.

Thank you for your subscription!

We have sent you an email — please confirm your email address by clicking the activation link in it.