Your integrated solution provider for measuring technology in pipe extrusion

Innovative products for sustainable success of our customers

For more than 35 years, the company has been using its innovative strength and know-how to realise ideas with a future. Efficiency, precision and the willingness to push boundaries make the products and services even better. As an integrated solution provider, iNOEX GmbH delivers intelligent and innovative solutions and services that create added value for customers. The products stand for high quality, reliability and user-friendliness.

The new appearance will celebrate its premiere with the launch of the redesigned website at the end of August 2022, as well as with a revised trade fair concept at the K show in Düsseldorf.

#iNSPIRATION #iNNOVATION #iNTEGRITY

At the K show in Düsseldorf, iNOEX will be presenting the latest product developments in the field of high-precision measuring and control technology as well as product premieres in radar technology. Innovative solutions for more efficient extrusion processes - whether for pipe, hose, cable, film or profiles - as well as exciting novelties and versatile application possibilities await you in Hall 10, Stand C46.

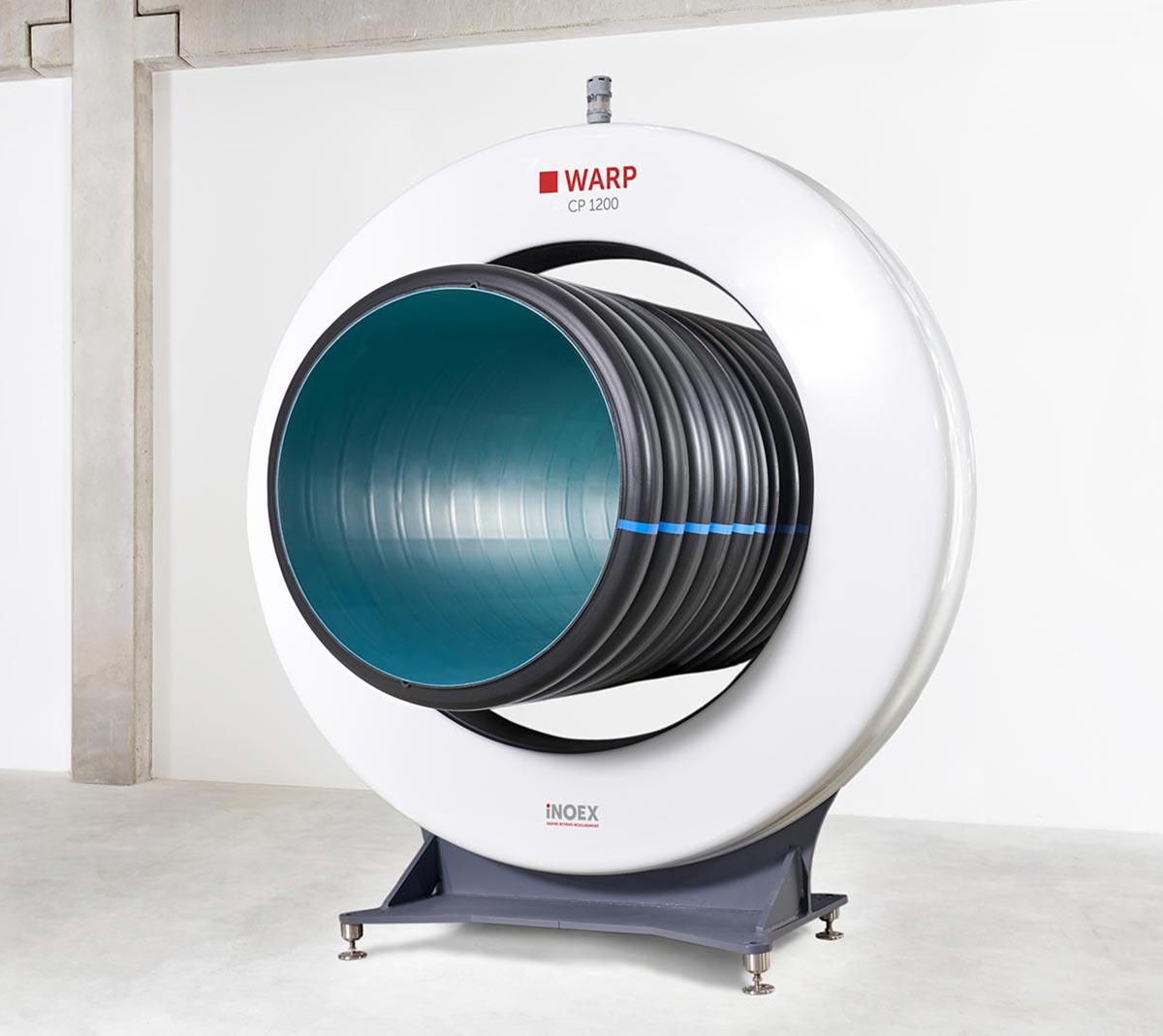

Measuring system with 8 radar-based wall thickness sensors for recording the various structures of a corrugated pipe. The outer and inner diameters as well as the wall thicknesses of the bell, the crest, the liner and the valley can be resolved. The system is available for large corrugated pipes with diameters from 300 mm.

The 8 sensors around the corrugated pipe scan it continuously. Since the corrugated tube has different structures, it is therefore necessary to assign the measurement data to the corresponding position on or in the pipe. The WARP-CP algorithms do this automatically and prepare the data for the user in such a way that he is provided with different graphics and corresponding measurement data for each structure.

Inline pipe measuring system for wall thickness and diameter measurement at up to 38 measuring points and 19 axes. More than 1100 measurements per second guarantee a complete measurement. The WARP 100 in is available in three sizes and can be used for measurements in the diameter range from 60 to 630 mm.

The specially developed optics allow the alignment of the radar wave to be focused on the centre of the pipe. The sensors are arranged in such a way that the measuring spots overlap, thus ensuring close-meshed coverage in the extrusion direction. The maximum line speed for 100 % coverage is up to 11.8 m/min. Measured variables such as wall thickness, diameter, ovality, eccentricity and process conditions (e.g. sagging) are precisely recorded, documented and used for automatic process control.

Mobile, radar-based hand-held measuring device for punctual wall thickness measurement, specially designed for medium and large pipe extrusion as well as for sheets. Wall thicknesses from 2 to 110 mm (depending on the material) can be measured. Whether as a quick centring aid in the start-up process, for final inspection of production or as a stock control device, the possible applications are very flexible.

Not only can wall thicknesses at pipe ends be measured, but also the course inside a pipe section or a sheet. The measurement is carried out at the push of a button and the last 100 measured values including the measuring angle on the pipe as well as the time stamp are stored.

These highlights of radar technology as well as the further developments in plastics measurement with radar sensors provide customers with decisive competitive advantages. Furthermore, tried and tested products are also presented at the latest technological level.

Measurement of wall thickness distribution, inner and outer diameter, ovality and eccentricity for single and multi-layer pipes and hoses. Thanks to a precise spatial resolution and repeatabilities in the µm range, the system reliably achieves exact measurement data. At high line speeds, the X-ray system - optionally two or three axes - delivers precise measurement results.

The standard systems are available for tube dimensions from 1 to 63 mm. The iXRAY series is user-friendly and the line operator only has to select the tube, hose or cable recipe to start the measurement. Furthermore, the X-ray units do not pose any risk to the operator. The radiation output is far below the permitted legal limits and other safety aspects ensure safe use.

The AUREX ERS uses the measuring technique of the Electronic Rotating Scanner (ERS) principle. With this active-passive measurement, every point of the measured object is detected 100 % in longitudinal and circumferential direction, so that even minimal tolerance deviations are detected.

Coextruded layers can also be detected as soon as they can be physically resolved with ultrasound. In addition to the AUREX ERS, the "Quality Check", a wall thickness error check, is optionally available. The "Quality Check" detects anomalies on the surface, in the material and on the inner surface of the pipe.

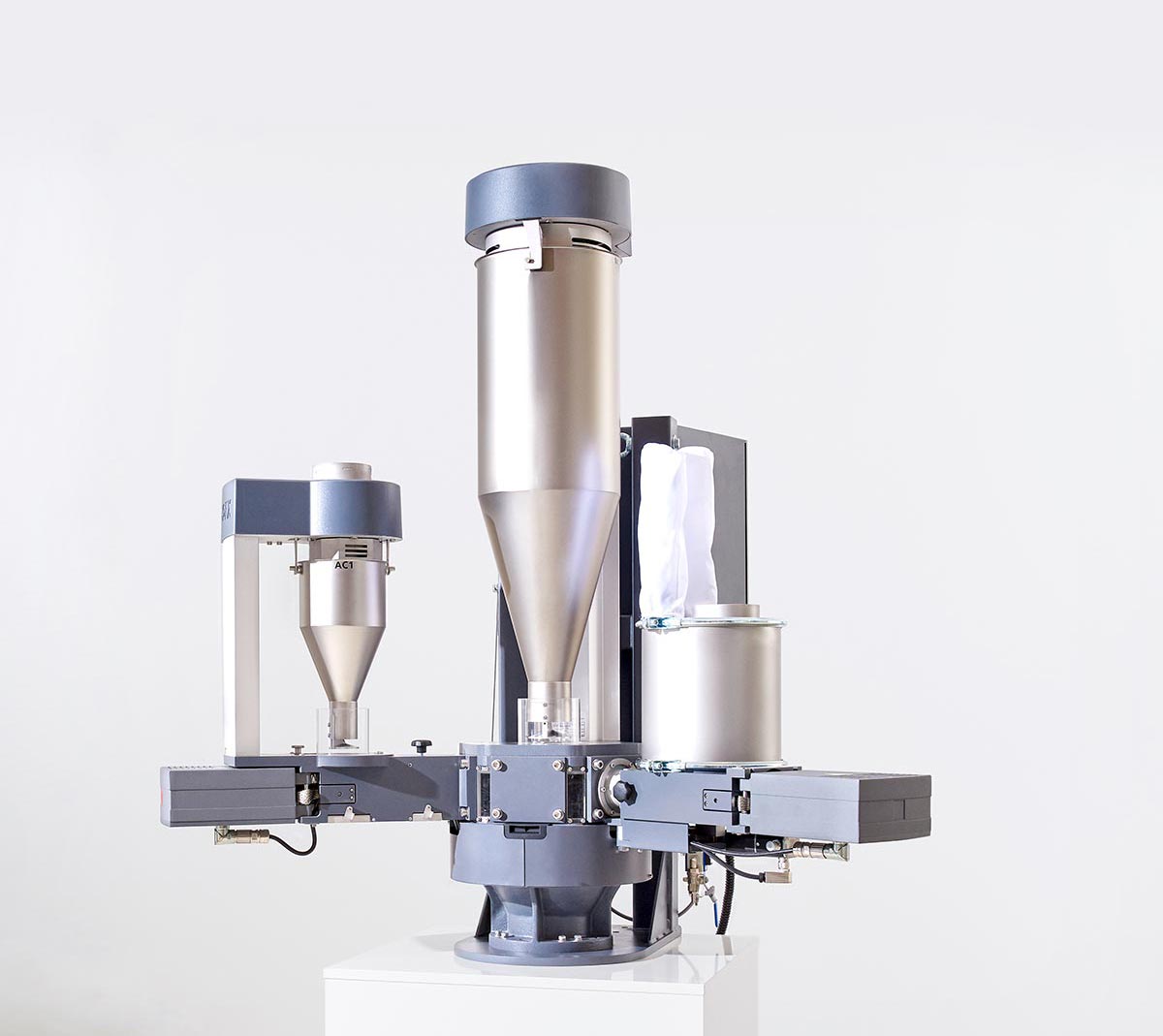

Gravimetric weighing is the basis for the automation of extrusion lines. Continuous and highly precise gravimetric weighing and level monitoring of solid and liquid materials, enable material savings through exact mass throughput and metre weight control.

The funnel weighers are suitable for a wide range of materials and, in addition to the high level of precision, also offer maximum flexibility through easy cleaning and a quick product change. They are controlled by means of an intuitive user interface.

At the K show, iNOEX will be exhibiting the following individual funnel weighers:

Central data storage for the collection of all process and quality data of the iNOEX systems in the extrusion line. Optimisation potentials can be identified and product-specific key figures analysed and evaluated. The software is installed as a virtual machine in the customer's network, so no additional hardware is required. OPC-UA as a standardised process data interface transfers the data. Integration of almost all types of interfaces is possible via the iDM Gateway.

By using the Grafana software, iDM 4.0 enables graphs, visualisations and data evaluations, data export as .csv or .xls, live data on the database server, use as a hall monitor as well as ready-made and freely configurable dashboards and reports for each connected system. Site-wide statistics such as overall line effectiveness and process capability and a notification function are also possible.