1993

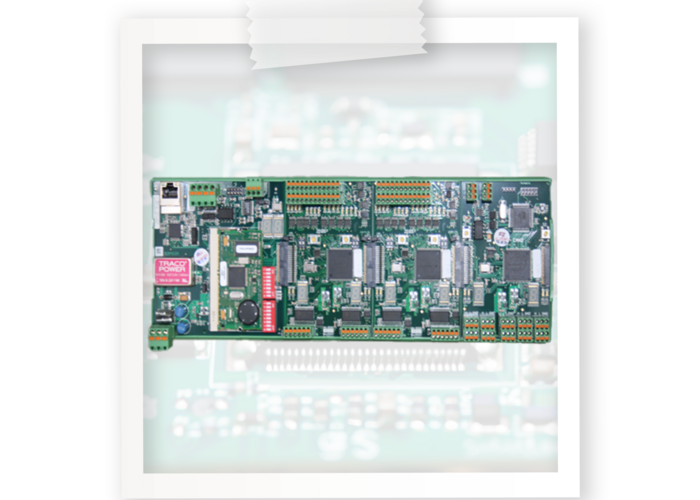

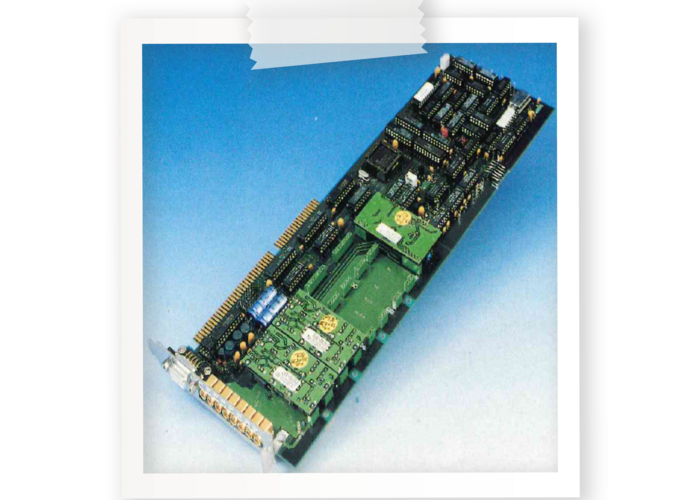

Launch of the Intelligent Gravimetric Sensor (IGS)

With the introduction of the Intelligent Gravimetric Sensor (IGS) in 1993, iNOEX sets another milestone in sensor technology. The IGS is not only able to measure material throughput precisely, but also to control it automatically in order to ensure continuous optimization of the production process.

Thanks to the integrated calculation of conveying data, the compact and versatile sensor can be connected to a wide range of equipment, underlining its flexible applicability. This innovation is still used in iNOEX's own processes today, and the associated software is continuously developed to meet the changing needs of the industry.

Facts about the IGS

- Material throughput measurement and control: The IGS accurately measures material throughput in real time and automatically controls it to continuously optimize the process.

- Continuous optimization: The sensor continuously calculates conveying data, resulting in efficient control of material flow.

- Compact design: The IGS is small and compact, making it easy to integrate into various applications and connect additional devices.

- Software support: The associated software has been specially developed by iNOEX and has been continuously developed and used since its introduction.

- Compatible usability: The IGS is versatile and can be connected and used with different systems.

- Application in the plastics industry: The sensor is particularly suitable for optimizing production processes in the plastics industry, where precise material control is essential.

- Important iNOEX innovation: The IGS is one of iNOEX's most important innovations and is still used today.

Subscribe to the newsletter

Subscribe to the newsletter and never miss exciting news about product development, events and internal topics from the iNOEX world again.

Thank you for your subscription!

We have sent you an email — please confirm your email address by clicking the activation link in it.